热交换器如何在清理后工作

换热器帮助控制液体温度在加工行业进行巴氏杀菌,灭菌,干净的(CIP)和其他卫生行动。在本文中,我们将突出显示how heat exchanges workduring CIP operations.

Heating systems for CIP为水和清洁剂提供温度控制。CIP refers to the equipment anda method for cleaning interior surfacesof管子, vessels, process equipment, filters, and配件没有拆卸。依赖CIP依赖CIP的行业包括乳制品,饮料,酿造,药物,biotechnology, and个人护理industries to achieve faster, less labor-intensive and more repeatable results than manual cleaning.CIP设计对运营商的化学暴露风险造成了较少。

Clean-in-place systemscan operate either in a single pass in which CIP hot water goes to a drain, or are-circulated systemwith CIP hot water returning to a central tank system.

In both cases, CIP systems include heat exchangers for heating cleaning fluids to the proper temperature.

Heating in CIP uses two techniques:

- Indirect contact of steam via heat exchangers in which heat is transferred from steam across a thermally conducting but an impermeable barrier, such as metal plates

- 直接接触蒸汽通过蒸汽注入液体液体

Because of the relatively high cost of direct steam injection and the potential impact of steam on processed fluids,间接接触板和框架热交换器通常优选,并且比CIP系统中的直接蒸汽喷射更常见。

CIP中使用的热交换器类型

Capacity and pressure requirements in CIP systems vary dramatically, and manufacturers have responded to demand with a variety of designs for heat exchangers.

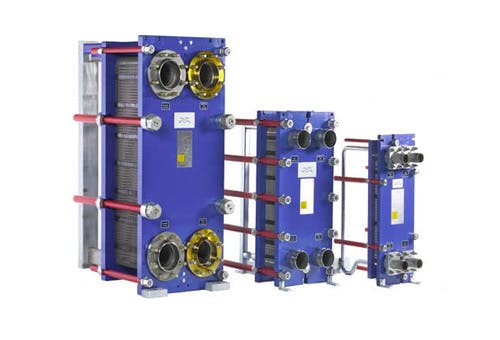

板材和框架热交换器

With a relatively low steam pressure requirement of around 50 psi,板和框架热交换器在CIP系统中很常见。高效率和适度的定价使它们成为许多CIP设计的首选。

- 可能需要蒸汽减速机降至50 psi

- Lower cost

- 可以通过添加/移除板来改变职责

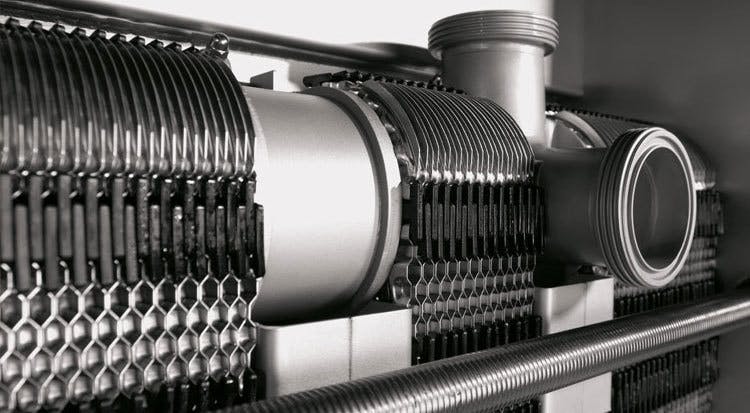

壳管热交换器

A simple, low maintenance in-line heating option. Common in many CIP systems butmay require higher steam pressures and volumes to sufficiently heat solutions quickly.

- 容纳更高的PSI,因此无需压力减速器

- 成本更高

- Cannot change duty later

100%不锈钢板换热器

Designed for tap and warm water applications to prevent trace nickel and copper leaking, a 100% stainless steel design is well-suited for tap water duties. 100% stainless is a safer alternative to conventional brazed heat exchangers because 100% of stainless designs are not treated with coatings.

- Minimizes metal release into the environment

- 用于加热和冷却

- Industry-standard port configurations and connections

板和框架热交换器如何工作

Indirect-contactplate and frame heat exchangersraise or lower fluid temperatures in processing systems using water or steam.“Indirect-contact” design means that the heating or cooling fluid does not mix withCIP fluids。相反,在热传导但不可渗透的屏障中从一个流体转移到另一个流体,例如特殊设计的金属板。

换热器feature two alternating fluid flow paths that prevent fluids from mixing.板色波纹产生防止或减少矿物质,蛋白质和其他加工液的污染的湍流。

板垫片密封板之间的通道,并将流体直接引入交替的通道。高温流体通过板式用低温流体交换热量。

为了确定框架中板的数量,工程师根据系统流速,加工流体的物理性质,可用的压力降低和温度要求来计算所需的传热。

Gasketed plate heat exchangers designed specifically for steam use are suitable for hot water sets in pasteurization and CIP heating.

They are also suitable for liquid-liquid or liquid-phase change applications if the operating pressures and temperatures are less than about 145 psi and 350°F.

Direct-contact steam injection for CIP

Direct-contact steam injection heatingin cleaning applications offers:

- Precise temperature control

- 降低能耗

- 低维护成本低于间接接触通过板和框架热交换器。

虽然直接接触注射提供100%的热效率,但其设备和化学成本远高于间接接触方法的成本。

While initial costs can be higher, direct-contact steam injection does offer some advantages:

- Installed in line with the CIP piping

- Typically more compact than indirect heat exchangers

- Transfers heat by injecting precisely metered amounts of steam from a plant’s steam supply into the CIP fluid

- Results in more rapid heat transfer and more efficient energy usage

- 节能可以相当大 - 在20-25%的范围内减少并不罕见

- Precisely metered injections of steam directly into the cleaning solution are typically quicker and more accurate than other heating options

加工操作必须确保饱和蒸汽供应,这是蒸汽调理的结果,以防止过热蒸汽或蒸汽供应不足。食品工业中的蒸汽质量必须满足“烹饪蒸汽”要求和生物技术行业,必须满足“清洁蒸汽”的规格。必须进行蒸汽调节以最大限度地提高传热,以及调节的化学品增加加工成本。

Steam condensation

Steam heat exchangersare thermally optimized for steam condensation duties for heating water and for heating clean-in-place (CIP) solution by means of steam and other heating and cooling applications. Operators modify steam heat exchangers by adding or removing plates.

Understanding Heat modulation

To optimize cleaning and achieve consistent, reliable results,CIP系统调制加热以调节到处理变量。Direct-contact steam heaters can be classified as either:

- 外部调制

- Internally modulated

Which refers to how the steam injected into the CIP fluid is controlled.

外部调制热量

外部调制的蒸汽加热器使用蒸汽压力控制阀调节注入CIP过程的蒸汽量。The valve is located in the supply steam piping.

At times, steam velocity and the volumes of steam and fluid mixing can vary widely over the operating range. Vibration, poor temperature control, and inefficiency result in some operating conditions. Tank spargers, which use external modulation, can experience steam hammer and vibration damage to tanks. Energy inefficiencies also can occur with this heating method when the steam does not completely mix and escapes from the tank.

Internal modulation of heat

With the internally modulated direct-steam injection heater, steam flow is controlled through a stem-plug assembly inside the heater.改变喷嘴的蒸汽放电区域改变通过喷嘴的蒸汽量并保持良好的混合特性。

内部调制的直接接触式蒸汽加热器inject metered amounts of steam into the CIP fluid through a variable-area steam nozzle.The nozzle design ensures constant steam pressure and velocity at the point where steam contacts the liquid, eliminating the potential for pressure upsets and ensuring smooth heater operation.

Internally modulated direct-steam injection heaters are cleaned by their own turbulent mixing action, usually sonic velocity steam, so they do not encounter fouling or scale buildup.

Indirect heat modulation with steam

Plate-and-frame and shell-and-tube designs may use steam instead of hot water to heat fluids indirectly (vs. via direct steam injection). In plate-and-frame steam-heating applications, the fluid to be heated and the steam doing the heating flow through alternating plate channels. In shell-and-tube steam-heating applications, the fluid to be heated flows through the tubes, and the steam circulates in the shell. In both cases, angle seat control valves regulate the amount of steam.

阀门改变流量和蒸汽压力以控制温度。传感器通过目标设定点温度监测实际温度,并向执行器表示相应的致动器。

Clean-in-place vs Steam-in-place

For the most part, theCIP过程是一个完全自动的过程,符合具体的过程要求。CIPis a series of defined steps using cleaning temperatures of up to 210°F.CIP保持湍流的5-7ft / sremoving impurities.

Steam-In-Place is an extension of the CIP process to add sterilization without having to disassemble the processing system and measuring equipment.

卫生过程的灭菌发生在CIP过程的末端,以确保在系统中仍然活跃的微生物在高温(> 121℃)下用热水或蒸汽杀死。

How to Clean a Heat Exchanger

TheJournal of Food Engineering指出矿物质的污垢,蛋白质到热交换器板上是一种令人担忧的食品工业由于效果污垢对传热率和整体系统效率进行了污垢,导致运营费用增加。

Should fouling occur in a heat exchanger, aCIP系统可在线清洁没有拆除设备。CIP还除垢石灰沉积物,钝化清洁的表面以减少对腐蚀的敏感性,并在排水前中和清洁液。

CIP systems connect directly to heat exchangers or via separator connections and circulate a mixture of heated non-toxic cleaning agents that remove scale, product deposits, and biofouling to restore performance.

Fabricated CIP systemssuitable for very large heat exchangers require custom engineering.

下一步

As you've learned, heat exchanger styles can vary widely based on a number of variables, which can make the proper selection for your process appear daunting. We're here to help!

无论您是需要零件要保留当前单位运行,可直接更换磨损或低效的热交换器,或新工艺的新单位,CSI可以支持您。

To learn how we can help, contact us today!

ABOUT CSI

Central States Industrial Equipment (CSI) is a leader in distribution of hygienic pipe, valves, fittings, pumps, heat exchangers, and MRO supplies for hygienic industrial processors, with four distribution facilities across the U.S. CSI also provides detail design and execution for hygienic process systems in the food, dairy, beverage, pharmaceutical, biotechnology, and personal care industries. Specializing in process piping, system start-ups, and cleaning systems, CSI leverages technology, intellectual property, and industry expertise to deliver solutions to processing problems. More information can be found atwww.xxshagua.com.。